1 Department of Management Studies, St. Joseph University, Dimapur, Nagaland, India

Creative Commons Non Commercial CC BY-NC: This article is distributed under the terms of the Creative Commons Attribution-NonCommercial 4.0 License (http://www.creativecommons.org/licenses/by-nc/4.0/) which permits non-Commercial use, reproduction and distribution of the work without further permission provided the original work is attributed.

In recent years, there has been an increasing focus on incorporating green business techniques into entrepreneurship activities, a concern shared by firms and researchers alike. Although developed nations have faced regulatory pressures to adopt environmentally friendly methods, this problem has received less attention in developing economies such as India. In light of the time sensitivity, it is crucial to identify the catalysts of green business adaptation into their entrepreneurial activity, specifically focusing on the essential variables among them.

The objective of this study is to identify and establish a cause-and-effect relationship between the elements that support green entrepreneurship, using the gray DEMATEL (Decision Making Trial and Evaluation Laboratory) technique. The distinctiveness of this research is its simultaneous emphasis on identifying factors that facilitate and establishing cause-and-effect links, which has not been investigated in previous studies. The creation of green manufacturing capabilities, obtaining funding for green innovation, getting loans from financial institutions easily, and following environmental regulations are the most important components of a comprehensive list of 10 factors that support green business.

Moreover, the study enhances its contribution by providing managerial and practical implications, with the purpose of supporting managers of the case organization in implementing green innovation techniques. This comprehensive method seeks to connect the divide between identifying factors that enable something and cultivating a more profound comprehension of how these factors are interconnected, in order to facilitate the implementation of sustainable entrepreneurship practices.

Green business, green entrepreneurship, sustainability

Introduction

The relationship between economic growth and the environment is highlighted in the concept of green economic growth, which seeks to harmonize the economy with its ecological underpinnings. An imperative task is to analyze several approaches to economic expansion that encompass diverse facets of socioeconomic advancement (Lawson, 2006). Both academic research and real-world evaluations focus on how to include eco-friendly activities in national development plans and policy actions. Both developed and developing countries are actively involved in these efforts. Things like institutional capacity, government directives, national development goals, and other resources that are available affect how policymakers make decisions. (Megwai et al., 2016).

The efficacy of green performance sustainability relies on the consistent capacity to implement and the congruence of environmental policies, as highlighted by study (Islam et al., 2012). Green entrepreneurs and their initiatives are essential for maintaining the sustainability of the green economy. Nevertheless, challenges such as volatile laws and bureaucratic hurdles in the corporate environment pose difficulties that impede the effective functioning and growth of these eco-friendly initiatives (Melay et al., 2017).

The integration of environmental sustainability into entrepreneurship is crucial for promoting the development of enterprises committed to advancing social progress. Green enterprises have a greater likelihood of long-term sustainability and tend to earn larger sales compared to businesses that do not follow environmentally conscious entrepreneurship principles (Charney & Libecap, 2003; Kirkwood & Walton, 2010; Oosterbeek et al., 2010; Rauch & Hulsink, 2015). Hence, proficiency in green entrepreneurship additionally facilitates the integration of technology in the creation of goods and services, promoting technology-based organizations and items (Rauch & Hulsink, 2015). The growing focus on the mindset of green entrepreneurship has prompted debates on the convergence of green knowledge and entrepreneurial conduct, specifically in the context of poor nations (Rauch & Hulsink, 2015).

Participating in environmentally-friendly business practices offers organizations the chance to adjust to shifts in the industry and strengthen their long-term competitive edge, placing themselves advantageously in the market. As a result, a growing number of organizations are adopting environmentally friendly strategies. Nevertheless, the execution of environmentally-friendly business practices necessitates the effective handling of numerous internal and external risk factors or obstacles, whether they are expected or unexpected (Su et al., 2014). Researchers have investigated the factors that contribute to the expansion of environmentally-friendly businesses, condensing successful case studies for enterprises to consult (Yi, 2014). Hwang et al. (2017) propose that the optimal strategy for fostering environmentally conscious enterprises is through government co-funding and incentives for training and technologies. The success of green business is determined by various factors, such as the endorsement from senior executives, the education and development of staff, cooperation among the supply chain, and the ever-changing nature of the environment (Chan et al., 2016; Dai et al., 2014, 2015; Sarkis et al., 2010).

Concurrently, studies on business failure strive to propose strategies that can avert substantial financial setbacks for companies (Wang & Wu, 2017). The study acknowledges the adage, “failure is the mother of success,” and emphasizes the valuable insights that may be derived from failure. Business failure, a common problem in the field of business and management, has been repeatedly noticed (Kherrazi & Ahsina, 2016). Emotional issues that result in business failure can be effectively dealt with by employing emotion-focused coping strategies, encouraging self-reflection, and eventually enhancing business circumstances (Byrne & Shepherd, 2015). Hence, comprehending the fundamental determinants of business success is vital for achieving future business prosperity.

To summarize, the current body of literature thoroughly explores the elements that contribute to the success of green businesses, while studies on business failures generally overlook the environmental side. This study seeks to fill this void by identifying the pivotal variables that contribute to the success of green businesses. This study enhances the theoretical understanding of green business by developing a framework that aims to influence success in this field. It complements existing studies that mainly focus on identifying success factors and provides a more comprehensive basis for the practical implementation of green business principles.

Through the examination of previous research, researchers can focus on the extraction, analysis, and evaluation of crucial variables. Büyüközkan and Güleryüz (2016) defined a total of 21 criteria categorized into five dimensions: technological, economic, political, social, and environmental. Jeng (2015) examined the significance of environmental uncertainty, asset specificity, and trust as indicators in a causal model of supply chain collaboration. Moreover, a firm undergoes a life cycle, progressing through stages of development and challenges (Al-Hadi et al., 2019).

Subsequently, the quantitative study was conducted using expert assessment to reveal the importance of each affecting element. The assessment procedure utilized the DEMATEL method, a well-established strategy frequently deployed in various researches for its straightforwardness. Nevertheless, the primary limitation of DEMATEL is its dependence on expert assessment, which may lead to possible inconsistencies. In order to tackle this issue, this study addresses it by integrating gray set theory (Xia et al., 2015). Gray set theory is applicable in circumstances characterized by partial clarity of knowledge, with the remaining portion being vague and uncertain. The system has the ability to account for missing information, hence improving the accuracy of the evaluation (Su et al., 2016). Hence, to thoroughly analyze the correlation between elements with enhanced precision and applicability, the integration of gray set theory and DEMATEL is employed. This integration allows for the incorporation of uncertainty, imprecise information, and ambiguity into the assessment process.

In this context, the present study has following research questions:

The study makes three significant contributions: First, it investigates the factors that influence green business, providing a thorough analysis of the subject. Second, it develops a framework, which enhances the construction of a theoretical framework. Finally, it combines gray set theory with DEMATEL to assess components, hence enhancing the precision and applicability of evaluation outcomes. The subsequent sections of this article are structured in the following manner: the second section provides a thorough analysis of the current literature on green business, including its key components and the use of gray DEMATEL to uncover possible factors that could contribute to the success of green enterprises. The third section offers an elaborate account of the research approach, which involves the application of gray DEMATEL (GDEMATEL) and analytical procedures. The fourth section entails the processing and analysis of the data, however, the fifth section scrutinizes the ramifications of this research. The sixth section concludes the investigation and specifies the limitations of this study.

Review of the Existing Literature

Review of the Literature on Green Business and the Elements that Influence it

Although environmental studies have experienced significant growth, the area of green entrepreneurship is still in its nascent phase. Pacheco et al. (2010) emphasize the presence of unsolved conceptual matters where Business Economics, Entrepreneurship, Finance, and Accounting meet. O’Neill and Gibbs (2016) propose that entrepreneurs frequently struggle with delineating the precise range of activities that meet the criteria for green entrepreneurship. In order to resolve this lack of clarity, researchers have endeavored to establish a precise definition or description of green entrepreneurship. Green Project (2012) defines it as a deliberate effort to tackle environmental and social concerns through entrepreneurial endeavors, notwithstanding the potential dangers, with the aim of achieving a favorable outcome for both the environment and financial stability. A green entrepreneur is further defined as an individual who takes the initiative to establish and oversee a business that is focused on being environmentally friendly in both its operations and the products it offers.

In their study, Costantini and Mazzanti (2012) suggest that green entrepreneurship can be defined by considering the technological aspects of production or the operations of a corporation. Dale (2018) characterizes it as a narrative-driven procedure in which an entrepreneur secures backing from stakeholders to pursue their aspirations. According to the literature, there is no commonly acknowledged definition of green entrepreneurship due to its early stage of development (Demirel et al., 2019).

Green business seeks to implement products, processes, services, and business models that are distinguished by their low carbon emissions, resource efficiency, or remanufacturing. Green businesses, when compared to their nearest competitors, operate and perform in a significantly more sustainable manner (Kanchan et al., 2015). In the current era of entrepreneurship, the advancement and updating of organizations require the use of environmentally friendly business strategies (Mioara & Mihai, 2014). Ilinitch and Schaltegger (1995) suggest integrating an environmental aspect into the strategic planning process of enterprises involved in environmentally conscious business. Kirchhoff (2000) supports the implementation of ecologically friendly materials, reduction of waste and pollution in the production process, and improvement of the biodegradability of the final product for enterprises engaged in green business. Lin et al. (2011a) employ a hybrid methodology to investigate the innovation capabilities of environmentally conscious businesses.

In the highly competitive contemporary business landscape, a multitude of variables can contribute to the demise of a corporation. Managerial cognition is recognized as a significant component contributing to failure, as stated by Cox and Vos (2005). Additional variables such as variable expenses, customer delays, lack of expertise in contracts, narrow profit margins caused by competition (Mahamid, 2012), and the choice of suppliers (Bohner & Minner, 2017), can also contribute to the collapse of a corporation. Environmentally-friendly firms can achieve sustainable development by implementing and improving effective green process management. This has been proved in industries such as real estate, agri-business, and related areas. Business operations can improve their environmental sustainability by applying business process reengineering with a strategic focus on ecological perspectives (Cui, 2017; Lan, 2011; Peng & Zhang, 2014). Chen and Wu (2015) examine how organizations’ perception of green business affects their adoption of green business strategies and overall business success.

Although numerous studies have examined the influence of specific factors, such as green human resources, on green business, only a few have taken into account the interrelationships between multiple components or the links between factors that contribute to the success or influence of green businesses. Hence, this study aims to identify the determinants of green business factors, facilitating a thorough investigation. The DEMATEL methodology is utilized to quantify the importance of each feature, while gray set theory is implemented to effectively address the problem of semantic uncertainty.

Literature on Application of Gray-DEMATEL

The DEMATEL method is an effective approach for examining the relationships between important elements in terms of their characteristics and strength. The direct impact matrix is used to identify the logical links between items and determine the influence and relevance of each aspect on others. Bai and Sarkis (2013) effectively demonstrated complex causal links between essential success elements using DEMATEL. Meanwhile, Xia et al. (2015) examined internal obstacles encountered by automotive parts remanufacturers and assessed causal barriers using a model framework. DEMATEL may also identify causal linkages and interacting influences among criteria, as demonstrated in studies conducted by Baykaso.png) lu and Gölcük (2017), Sharma et al. (2017), and Tsai et al. (2016).

lu and Gölcük (2017), Sharma et al. (2017), and Tsai et al. (2016).

Nevertheless, the DEMATEL method is constrained by the imprecise nature of human assessments and the challenge of accurately quantifying numerical values (Govindan et al., 2016a). The system fails to consider a hierarchical organization and uses an analytical method that lacks complete information. Gray set theory addresses the limitations of uncertain systems with unknown knowledge by augmenting partial information (Su et al., 2016). Vafadarnikjoo et al. (2015) utilized GDEMATEL to identify significant project risk categories, but Ren et al. (2017) performed a more accurate assessment of the impact of sludge on the long-term viability of energy systems.

While GDEMATEL has been utilized in various research studies, such as exploring key attributes of supply chain risks and uncertainties and analyzing the implementation of sustainable consumption and production (Luthra et al., 2017; Wu et al., 2017), there is a scarcity of research on the application of GDEMATEL to investigate failure factors of green business. The focus of our study is to examine the ambiguity surrounding expert viewpoints on crucial determinants of green company failure. Hence, the use of gray set theory and gray-DEMATEL is deemed pragmatic and appropriate for this inquiry. Thus, our research aims to fill this research gap by providing enhanced theoretical support and practical guidance.

Methodology

This study employs a two-part methodology, with the first part being the use of Dalkey and Helmer’s (1963) Delphi method to identify enablers. The Delphi approach entails systematically defining all relevant parts of the study and then collecting expert opinions through iterative rounds of deliberation until a consensus is reached on the key factors. Through a comprehensive literature analysis, we identified an initial set of 13 factors for our study. Following that, these facilitators engaged in several rounds of deliberations with experts, resulting in a definitive consensus on 10 facilitators for subsequent examination utilizing the gray DEMATEL technique.

The Battelle Memorial Institute in Geneva developed the DEMATEL methodology, a thorough method for formulating and analyzing the interdependencies among various elements. This is accomplished by using relationship matrices and digraphs to establish causal linkages (Gabus & Fontela, 1973). DEMATEL is a beneficial method for examining cause-and-effect connections in intricate structural models. This sets it apart from other multi-criteria decision-making techniques such as Analytical Hierarchical Process (AHP) and TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution), which do not explicitly establish cause-and-effect relationships (Kim, 2006; Tseng, 2009; Wu et al., 2010).

Although DEMATEL is proficient in examining causal connections, its drawback is in addressing ambiguity and expert conflicts arising from inadequate information. In order to tackle these difficulties, the research utilizes gray system theory, which is particularly advantageous in dealing with ambiguous and partial information, particularly in instances involving discrete data. Gray system theory is a useful approach for dealing with uncertainties and limited data in situations with small sample sizes. It helps to solve the problems that arise from making incorrect decisions (Liu & Qiao, 2014). The combination of gray and DEMATEL methodologies has been successfully applied in various fields, including service quality expectation, exploration of core competencies, green supplier development, business process management, FMEA assessment, modeling enablers of supply chain risk mitigation, analysis of barriers for automotive parts remanufacture, and analysis of barriers for environmentally friendly products (Bai & Sarkis, 2013; Chang et al., 2013; Fu et al., 2012; Lin et al., 2011a; Rajesh & Ravi, 2015; Shao et al., 2016; Tseng, 2009; Xia et al., 2015).

Table 1. Evaluation of Linguistic Abilities and the Corresponding Grading System.

.jpg/10_1177_0976030X241292124-table1(1)__600x136.jpg)

Source: Salem et al. (2020).

The present investigation utilizes a blend of the gray system and DEMATEL methodologies to clarify the connections among factors that facilitate green innovation. The following outline outlines the methodological steps for the gray DEMATEL approach:

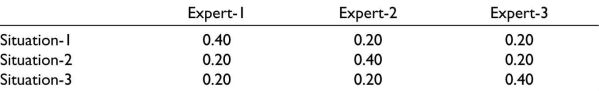

Step 1: Initial relationship matrix creation for every expert

Let “n” be the number of enablers of green innovation and “k” represent the number of respondents selected for the research. Each participant is given the task of rating, on a scale of 0 to 5, the relative influence of facilitator Bi over facilitator Bj. From “no influence” to “very high influence,” the scale values indicate the various impact levels among the “n” facilitators that have been found. The linguistic assessments and the gray numbers that correspond with them are shown in Table 2. Following that, a set of “k” initial relation matrices were produced utilizing the participants’ impact evaluations.

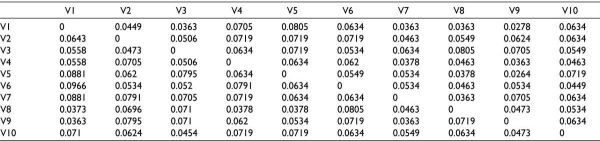

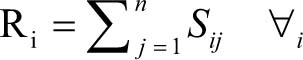

Table 2. Normalized Direct Crisp Relationship Matrix X for the Success of Green Entrepreneurship.

Step 2: Deriving the matching grayscale matrix for each initial connection matrix

Using the values acquired in Step 1 and Table 2. The process of creating higher and lower value ranges yields the gray matrices, as shown in Table 2 (Ju-Long, 1982; Julong, 1989; Rajesh & Ravi 2015).

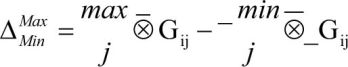

(1)

(1)

Where .png/image(47)__32x36.png) refers gray relational matrix for expert l, showing the relationship between factors.

refers gray relational matrix for expert l, showing the relationship between factors.

Step 3: Obtaining the average of gray relation matrices

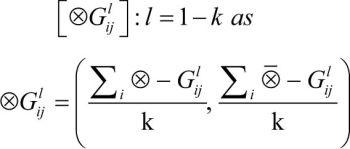

The average gray relational matrix, represented as .png) , is computed by combining the “k” gray relation matrices acquired.

, is computed by combining the “k” gray relation matrices acquired.

(2)

(2)

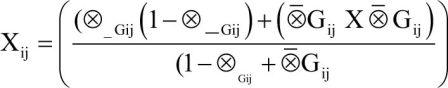

Step 4: Compute crisp matrices using average gray matrices

By employing a three-step technique, akin to the modified-CFCS method, one can obtain clear matrices, as evidenced in prior research conducted by Rajesh and Ravi (2015), Rajesh et al. (2015), and Xia et al. (2015).

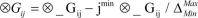

(3)

(3)

Where .png) represents the normalized lower limit value of the gray number

represents the normalized lower limit value of the gray number .png)

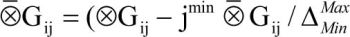

(4)

(4)

Where .png) denotes the normalized upper limit value of the gray number

denotes the normalized upper limit value of the gray number .png)

(5)

(5)

2. Calculate total normalized crisp value

(6)

(6)

3. Compute final crisp values

(8)

(8)

And

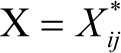

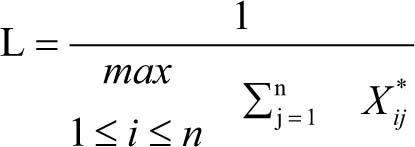

Step 5: Creating a standardized direct-relationship matrix

The normalized direct-relation matrix “N” is obtained by using Equations (9) and (10). The elements in this matrix are constrained between the range of 0 and 1.

(9)

(9)

(10)

(10)

Where the variable N represents the normalized direct-relation matrix, L represents the normalization factor, and X represents the initial crisp relationship matrix.

Step 6: Calculate the total relation matrix “S” by applying Equation (11)

(11)

(11)

Equation (11) can be expressed as S equals N multiplied by the inverse of (I minus N), where I denotes an identity matrix.

Step 7: Acquire informative parameters

The symbol R represents the sum of rows, while the symbol C represents the sum of columns. Equations (12) and (13), when applied, yield the following representation of the calculation:

(12)

(12)

(13)

(13)

Where

Ri represents the sum of row elements in the total relation matrix S for row i, it gives us the total effect that factor i has on all other factors.

Cj represents the sum of column elements in the total relation matrix S for column j, In other words, it gives us the total effect that other factors have on factor j.

Step 8: Establish a casual diagram and diagraphs

A causal diagram is created by utilizing the values derived from Equations (12) and (13).

Data Collection and Analysis

This study constructs the characteristics of green entrepreneurship based on existing literature. Subsequently, 10 criteria are chosen to examine the influential details of green entrepreneurship, which will be detailed below.

Many organizational activities are included in environmental management practices, such as the design of products, manufacturing equipment, raw material inputs, production information, material packaging, organizational technology, and waste management procedures (Shrivastava & Hart, 1995). By putting effective planning into practice and getting top management support for environmental management and improvement, organizations can accomplish major innovations (Lee et al., 2014).

Environmental commitment encompasses an organization’s environmental management policies and the level of awareness among employees on the advantages of various environmental initiatives and their significance (Simpson et al., 2007). The degree to which a corporation addresses the requests from stakeholders for environmentally friendly products is mostly determined by its level of dedication to environmental concerns (Aragon-Correa & Sharma, 2003; Henriques & Sadorsky, 1999). Green operational practices refer to operations that pertain to both products and processes, aiming to minimize their environmental impact (Gilley et al., 2000). With respect to activities associated with products, this involves the development and promotion of environmentally sustainable items that encourage reusability, recycling, and easy disposal. On the other hand, process-related practices place emphasis on the design and implementation of industrial procedures that produce minimal environmental impact, with the ultimate goal of attaining almost no waste production (De Ron, 1998). This can be achieved by implementing cleaner technology and implementing effective waste management and disposal systems (De Ron, 1998; Klassen & Whybark, 1999). Moreover, communication strategies are designed to improve a company’s reputation and standing both in society and among stakeholders by promoting the firm’s environmental accomplishments and methods (Aragón-Correa, 1998; Florida & Davison, 2001).

The term “green manufacturing capability” describes the set of organizational, financial, human, technological, and physical resources that are applied in a manufacturing plant to enhance its environmental performance. These resources are coordinated by organizational procedures (Grant, 1991; Nelson & Winter, 2009). An organization can become more green by using methods that aim to cut down on waste and pollution, make products that are better for the environment, and include environmental management systems like ISO in the production process (Maruthi & Rashmi, 2015; Nikbakhsh, 2009; Sarkis, 2001; Somsuk & Laosirihongthong, 2016; Zhu et al., 2008).

Financial institutions exhibit a strong commitment to environmental preservation and a willingness to finance initiatives that benefit the environment. Businesses can benefit from this trend by securing affordable loans at favorable interest rates to facilitate the development of new sustainable and eco-friendly goods (Azapagic, 2004; Govindan et al., 2016b; Jenkins & Yakovleva, 2006; Mathiyazhagan et al., 2013; Wilson & Nayee, 2002).

Integrating environmentally friendly practices into the supply chain enables firms to attain improved cost advantages and operational efficiencies. Green products have greater perceived value among customers, especially in larger organizations, which allows smaller enterprises to demand higher pricing for their products (Lee, 2008). Organizations have the potential to attain financial benefits through the adoption of innovative strategies for product development, which can result in price reductions (Berkel, 2007; Govindan et al., 2016b). The implementation of green innovation strategies enables organizations to broaden their presence in international markets, thereby facilitating the procurement of new companies (Chiou et al., 2011; Govindan et al., 2016b; Mathiyazhagan & Haq, 2013).

Green manufacturing capability refers to the combination of physical, financial, human, technological, and organizational resources within a manufacturing plant. These resources are integrated through organizational routines to improve the firm’s environmental performance (Grant, 1991; Nelson & Winter, 2009). Green manufacturing capabilities are established through the implementation of strategies that place an emphasis on the prevention of environmental damage, waste reduction, and pollution control. This includes integrating environmental management systems such as ISO into the manufacturing process and designing products that adhere to environmentally favorable standards (Maruthi & Rashmi, 2015; Nikbakhsh, 2009; Sarkis, 2001; Somsuk & Laosirihongthong, 2016; Zhu et al., 2008).

Designing for green products entails the deliberate process of creating a product that minimizes its environmental footprint during its complete lifespan. This entails reducing the use of materials and energy, removing harmful by-products, and promoting the reuse and recycling of resources without incurring additional costs for the product (Eltayeb et al., 2011; Hassan et al., 2016; Mudgal et al., 2009; Sarkis, 2003; Somsuk & Laosirihongthong, 2016).

Gaining insight into the market need for environmentally friendly products enables firms to develop a strategic plan for creating innovative green solutions. Consumers are becoming more conscious of ecologically sustainable items and are displaying a higher level of selectivity in their preference for eco-friendly goods (Chen, 2008; Zhou et al., 2009). Smaller firms that rely on larger entities for their business are obligated by these larger organizations to use environmentally friendly practices in their manufacturing processes, which in turn promotes the development of sustainable technologies (Chiou et al., 2011; Hsu & Hu, 2009).

Result and Analysis

Mere identification of the factors listed in Table 3 is insufficient to achieve the goal of this study. According to the research conducted by Ouyang et al. (2016), Pajer et al. (2017), and Xia et al. (2015), which primarily focused on expert selection, we have asked three experts to assess the direct impact of each component on others. The panel comprised a university scholar, a government representative, and a manager from a sustainable food company. These highly experienced professionals, each with more than 12 years of expertise in the field, are equally important in providing insights for a comprehensive analysis of the elements. As a result, each expert is assigned an equal weight of 0.25. A sensitivity analysis on this variable will be conducted in the future.

Table 3. Proposed Factors Influencing Green Entrepreneurship.

.jpg/10_1177_0976030X241292124-table3(1)__389x480.jpg)

To construct a matrix comprising 10 criteria related to linguistic characteristics, a 10×10 gray direct-relation matrix is computed. By adhering to the guidelines outlined in the third section, we are able to generate a normalized direct-relation matrix X (see Table 2).

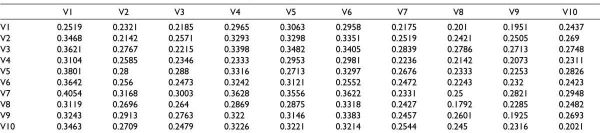

In addition, we also produce the comprehensive relationship matrix M (see Table 4). Subsequently, the dataset (R+D, R.png) D) is calculated, and a Cartesian coordinate system is built utilizing the processes delineated in the preceding sections. Let θ denote the sum of the mean and the standard deviation for the original value. In this case, θ is equal to 0.2565 plus 0.0589, which gives a value of 0.3154.

D) is calculated, and a Cartesian coordinate system is built utilizing the processes delineated in the preceding sections. Let θ denote the sum of the mean and the standard deviation for the original value. In this case, θ is equal to 0.2565 plus 0.0589, which gives a value of 0.3154.

The study uncovers the cause variables, effect factors, and connections among components that contribute to the success of green businesses by referring to Table 5. Elaborate elucidations are presented subsequently.

Table 4. Total Relation Matrix M for the Success of Green Entrepreneurship.

Table 5. Cause and Effect Parameters for the Success of Green Entrepreneurship.

Causal/Effect Factors

The study also ranks the causal facilitators according to the values of (Ri - Cj) for all i = j. In order to determine which enablers in the causative group require control and which can be addressed first, it is helpful to characterize and prioritize them. This is because the less mobile enablers in the causal group are the ones that can have the most impact on the effect group enablers (Lin et al., 2011b; Wu & Lee, 2007). The ranking of causal facilitators is as follows: The following values are in the order of importance: V7, V9, V3, V8, V10, V2, V5, V6, V4 and V1. Based on this classification, the categories include resources for green innovation (V7), Cost reduction and new business prospects (V9), and Green operating and communication methods (V3). The table displays the Market Demand (V8), the Ease of obtaining loans from financial institutions (V10), and the environmental commitment of the firm (V2). Enabling factors such as the development of green manufacturing capabilities (V5), the design of goods that are green and sustainable (V6), green purchasing (V4), and the implementation of environmental management practices (V1) all work together harmoniously.

Correlation Between Factors

A large number of criteria, either acting as cause group criteria or as effect group criteria, are often involved in complicated choice situations. Because several aspects are interdependent, enhancing just one of them will not lead to a better system as a whole. Consequently, enhancing variables in cause groups requires identifying this reliance relationship (Govindan et al., 2016b). This will improve effect group criteria and the system as a whole. In light of this, this study used a mix of gray and DEMATEL methodologies to identify the factors that influence the success of green business and the relationships between them. To exclude effects that were not statistically significant, a cutoff value of 0.262 was used. There are major ramifications for the examined company’s managers from combining gray and DEMATEL techniques.

The precedence of the enablers is determined by the values of (Ri + Cj): The following order of importance: V5, V6, V1, V4, V7, V3, V2, V10, V9, and V8. This ranking indicates that the most influential factor for the success of green business is developing green manufacturing capabilities (V5). The ability to manufacture in a way that reduces waste and pollution is one example of green manufacturing capabilities, which can greatly improve an organization’s environmental performance. According to Nikbakhsh (2009), Maruthi and Rashmi (2015), and Somsuk and Laosirihongthong (2016), most organizations currently use traditional manufacturing technologies. However, in order to transition to green manufacturing technologies, they will need to implement innovative techniques for cost control. This will encourage innovation within their organizations. The Market Demand (V8) is the primary causal factor. In contrast “Environmental commitment of the firm” (V2) is the least correlated with other factors (Cui et al., 2019).

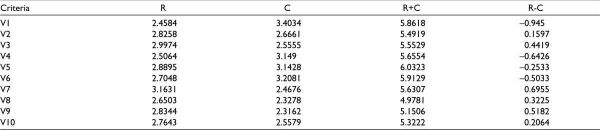

Sensitivity Analysis

Sensitivity analysis is a method employed to evaluate the reliability and resilience of a methodology. Sensitivity analysis can be conducted using several approaches. One specific strategy involves adjusting the weight assigned to a certain expert to evaluate its impact on the overall system (Emovon et al., 2016; Rajesh & Ravi, 2015). Given that the selected experts meet the criterion of possessing a minimum of 12 years of expertise, an equal weight can be initially allocated to each expert. Afterwards, the weights can be modified for each case based on the subsequent rules. In this procedure, one expert is allocated a greater weight, while the other experts are awarded equal weights, and the outcomes are calculated accordingly. Assigning higher weights to each of the four experts individually results in the creation of four different scenarios. Table 6 provides a comprehensive presentation of the specifics of the four situations (Cui et al., 2019).

Table 6. Weights Were Assigned to Different Analysts During the Sensitivity Analysis.

Source: Cui et al. (2019).

A distinct total relationship matrix is created for each scenario, from which different values for (Ri + Cj) and (Ri – Cj) are obtained. Table 6 presents the ranking of enablers based on their (Ri – Cj) values across different scenarios.

The sensitivity analysis results demonstrate that there is no partiality in the findings derived from the three separate situations. The table unequivocally illustrates that, in each of the three scenarios, the C7 and C5 consistently hold the top two positions. This trend is applicable not only to affect group entrepreneurs but also to entrepreneur that are rated last.

Discussions

The worldwide community has increasingly recognized the importance of environmental sustainability, leading both producers and consumers to actively search for methods to reduce the negative effects of industrialization and growing product demand on the environment. Nevertheless, the need for organizational changes arises due to challenges such as increasing pricing and decreasing product life cycles. Considering this, the study first identified the key drivers influencing the adoption of green entrepreneurship in North East India... The most prominent among these were the establishment of green manufacturing capabilities and the availability of resources of green entrepreneurship, as indicated by the gray-Decision Making Trial and Evaluation Laboratory (DEMATEL) method.

The DEMATEL methodology is particularly advantageous since it categorizes aspects into causal and effectual groupings, offering a systematic approach to elucidating the interconnections among green business elements. This study demonstrated that the DEMATEL method identified resources for green innovation, green manufacturing capabilities, and the accessibility of loans from financial institutions as significant causal factors influencing the success of green entrepreneurship. This study indicates that entrepreneurs ought to prioritize the acquisition of critical resources, including innovative technologies and a proficient personnel, to develop sustainable manufacturing capabilities. Access to these resources allows companies to reduce environmental impact while promoting innovation.

The gray DEMATEL method elucidates the cause-and-effect links among green business aspects by synthesizing expert evaluations and mitigating uncertainty through the application of gray set theory. This hybrid approach enhances the accuracy of factor ranking and enables entrepreneurs to pick those with the most significant causal influence on green innovation.

The research identified 10 pivotal characteristics affecting green entrepreneurship, ranked according to the DEMATEL methodology. This ranking aids entrepreneurs in comprehending the interconnections among many aspects, facilitating better strategic decision-making in the adoption of sustainable practices. Environmental management techniques, green purchasing, and internal organizational collaboration are recognized as significant influencing elements. By addressing these issues, entrepreneurs can enhance the causal determinants of green entrepreneurship.

The study has several implications for entrepreneurs and practical applications.

The gray DEMATEL method has proven to be an effective tool for identifying the drivers of green entrepreneurship in North East India. It allows for a clearer understanding of the relationships between different green business factors, helping entrepreneurs prioritize the most impactful aspects for driving innovation and sustainability

Conclusion and Implications of the Research

Environmental sustainability has gained significant recognition worldwide. Producers and consumers are discovering methods to mitigate the environmental impact of industrialization and increasing product demand. However, escalating prices and diminishing product life cycles represent challenges that can only be mitigated through organizational innovations. Accordingly, this study initially identified the determinants of green entrepreneurship and subsequently employed the gray DEMATEL methodology to analyze the interrelationships among these determinants, differentiating between causal and effect factors.

The elements of green entrepreneurship are typically interrelated; the DEMATEL methodology assists entrepreneurs in categorizing these elements into causal and effectual groups, identifying which elements influence others. By concentrating on those elements with the greatest causal impact, entrepreneurs can effectively implement green entrepreneurship initiatives within their organizations.

This study identifies 10 characteristics of green entrepreneurship and employs the DEMATEL technique to rank these factors and ascertain their interdependencies, yielding several managerial and practical consequences.

This study identifies the variables of green entrepreneurship and establishes the causal relationships among them. The causal link enables entrepreneurs to determine which drivers of green innovation warrant greater attention and which can be deprioritized.

Experts emphasized that entrepreneurs should prioritize the development of resources for green entrepreneurship within their organizations, encompassing essential equipment, technology, and skilled personnel. With the requisite resources, firms can cultivate green entrepreneurial capabilities, thereby diminishing their environmental impact. To effectively execute green entrepreneurship, entrepreneurs must initially focus on the driving factors of three preeminent elements. DEMATEL analysis enables entrepreneurs to understand the causal relationships among many components, hence facilitating the precise implementation of green entrepreneurship within their organizations.

Additional sensitivity analysis assists entrepreneurs in confirming the absence of bias among experts and the stability of the results obtained. These results can subsequently inform the development of the company’s future strategy, enabling entrepreneurs to concentrate on the critical factors identified in the study and to devise policies and frameworks aimed at enhancing these factors, thereby facilitating the overarching objective of implementing green entrepreneurship within the organization.

Moreover, the findings of this study possess considerable societal ramifications. Through the promotion of green entrepreneurship, enterprises can aid in mitigating environmental deterioration and advancing sustainable economic development. The advancement of green manufacturing capabilities not only minimizes waste but also generates employment prospects in environmentally aware industries. The results indicate that the incorporation of eco-friendly business practices will yield enduring social and environmental advantages, consistent with national sustainability objectives.

Limitations and Scope of Future Work

The current research has several constraints. Primarily, it concentrates solely on entrepreneurs hailing from the North East region, thereby limiting the applicability of its conclusions to entrepreneurs in different geographical areas. To evaluate the suitability and accuracy of the study in various situations, it is essential to conduct a comparison analysis across different states or regions. This analysis might involve either using the same criteria or different ones.

Furthermore, the analysis relies solely on the viewpoints of a mere three specialists in this particular instance. A larger and more diverse sample of experts could be included in future research to increase the statistical reliability of the study. This would enhance the development of a more holistic comprehension of the determinants impacting green entrepreneurship.

In addition, it would be advantageous for the study to investigate other Multi-Criteria Decision Making (MCDM) techniques, such as Interpretive Structural Modeling (ISM). An examination of the ISM and DEMATEL results in comparison could provide valuable insights on the coherence and precision of the findings.

Additionally, in future studies utilizing the gray DEMATEL approach, it may be beneficial to utilize the methodology suggested by Bai and Sarkis (2013). This process entails the conversion of gray numbers into real numbers following the computation of the prominence relationship. The purpose of this improvement is to mitigate the risk of information loss during the conversion process, hence improving the precision and dependability of the outcomes achieved using gray DEMATEL.

Declaration of Conflicting Interests

The author declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Funding

The author received no financial support for the research, authorship and/or publication of this article.

ORCID iD

Sethupathy K.  https://orcid.org/0000-0002-9308-4180

https://orcid.org/0000-0002-9308-4180

Al-Hadi, A., Chatterjee, B., Yaftian, A., Taylor, G., & Hasan, M. M. (2019). Corporate social responsibility performance, financial distress and firm life cycle: Evidence from Australia. Accounting and Finance, 59(2), 961–989.

Aragón-Correa, J. A. (1998). Strategic proactivity and firm approach to the natural environment. Academy of Management Journal, 41(5), 556–567. https://doi.org/10.2307/256942

Aragon-Correa, J. A., & Sharma, S. (2003). A contingent resource-based view of proactive corporate environmental strategy. Academy of Management Review, 28(1), 71–88. https://doi.org/10.5465/amr.2003.8925233

Azapagic, A. (2004). Developing a framework for sustainable development indicators for the mining and minerals industry. Journal of Cleaner Production, 12(6), 639–662. https://doi.org/10.1016/S0959-6526(03)00075-1

Bai, C., & Sarkis, J. (2013). A grey-based DEMATEL model for evaluating business process management critical success factors. International Journal of Production Economics, 146(1), 281–292. https://doi.org/10.1016/j.ijpe.2013.07.011

Baykaso?lu, A., & Gölcük, ?. (2017). Development of an interval type-2 fuzzy sets based hierarchical MADM model by combining DEMATEL and TOPSIS. Expert Systems with Applications, 70, 37–51. https://doi.org/10.1016/j.eswa.2016.11.001

Bergmiller, G. G., & McCright, P. (2009). Parallel models for lean and green operations.

Berkel, V. R. (2007). Eco-efficiency in the Australian minerals processing sector. Journal of Cleaner Production, 15(8), 772–781.

Bohner, C., & Minner, S. (2017). Supplier selection under failure risk, quantity and business volume discounts. Computers and Industrial Engineering, 104, 145–155. https://doi.org/10.1016/j.cie.2016.11.028

Büyüközkan, G., & Güleryüz, S. (2016). An integrated DEMATEL-ANP approach for renewable energy resources selection in Turkey. International Journal of Production Economics, 182, 435–448. https://doi.org/10.1016/j.ijpe.2016.09.015

Byrne, O., & Shepherd, D. A. (2015). Different strokes for different folks: Entrepreneurial narratives of emotion, cognition, and making sense of business failure. Entrepreneurship Theory and Practice, 39(2), 375–405. https://doi.org/10.1111/etap.12046

Chan, H. K., He, H., & Wang, W. Y. (2012). Green marketing and its impact on supply chain management in industrial markets. Industrial Marketing Management, 41(4), 557–562. https://doi.org/10.1016/j.indmarman.2012.04.002

Chan, H. K., Yee, R. W., Dai, J., & Lim, M. K. (2016). The moderating effect of environmental dynamism on green product innovation and performance. International Journal of Production Economics, 181, 384–391. https://doi.org/10.1016/j.ijpe.2015.12.006

Chang, K. H., Chang, Y. C., & Tsai, I. T. (2013). Enhancing FMEA assessment by integrating grey relational analysis and the decisionmaking trial and evaluation laboratory approach. Engineering Failure Analysis, 31, 211–224. https://doi.org/10.1016/j.engfailanal.2013.02.020

Charney, A. H., & Libecap, G. D. (2003). The contribution of entrepreneurship education: An analysis of the Berger program. International Journal of Entrepreneurial Education, 1, 385–418.

Chen, J. H., & Wu, S. I. (2015). A comparison of green business relationship models between industry types. Total Quality Management and Business Excellence, 26(7–8), 778–792. https://doi.org/10.1080/14783363.2014.884309

Chen, Y. S. (2008). The driver of green innovation and green image–green core competence. Journal of Business Ethics, 81(3), 531–543. https://doi.org/10.1007/s10551-007-9522-1

Chiou, T.-Y., Chan, H. K., Lettice, F., & Chung, S. H. (2011). The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transportation Research Part E: Logistics and Transportation Review, 47(6), 822–836. https://doi.org/10.10.1016/j.tre.2011.05.016

Costantini, V., & Mazzanti, M. (2012). On the green and innovative side of trade competitiveness? The impact of environmental policies and innovation on EU exports. Journal of Research Policy, 41(1), 132–153. https://doi.org/10.1016/ j.respol.2011.08.004

Cox, C., & Vos, E. (2005). Small business failure rates and the New Zealand retail sector: Perceptions of shopping mall managers. Small Enterprise Research, 13(2), 46–59. https://doi.org/10.5172/ser.13.2.46

Cui, L. (2017). Fuzzy approach to eco-innovation for enhancing business functions: A case study in China. Industrial Management and Data Systems, 117(5), 967–987. https://doi.org/10.1108/IMDS-02-2017-0041

Cui, L., Chan, H. K., Zhou, Y., Dai, J., & Lim, J. J. (2019). Exploring critical factors of green business failure based on Grey-Decision Making Trial and Evaluation Laboratory (DEMATEL). Journal of Business Research, 98, 450–461. https://doi.org/10.1016/j.jbusres.2018.03.031

Dai, J., Cantor, D. E., & Montabon, F. L. (2015). How environmental management competitive pressure affects a focal firm’s environmental innovation activities: A green supply chain perspective. Journal of Business Logistics, 36(3), 242–259. https://doi.org/10.1111/jbl.12094

Dai, J., Montabon, F. L., & Cantor, D. E. (2014). Linking rival and stakeholder pressure to green supply management: Mediating role of top management support. Transportation Research Part E: Logistics and Transportation Review, 71, 173–187. https://doi.org/10.1016/j.tre.2014.09.002

Dale, G. (2018). The Emergence of an Ecological Karl Marx: 1818 – 2018. The Legacy of the Political/Economist is Fiercely Contested, 1.7. Retrieved on 13/7/2019 via https://climatecommunismandtheageofaffluencereview.org/

Dalkey, N., & Helmer, O. (1963). An experimental application of the Delphi method to the use of experts. Management Science, 9(3), 458–467. https://doi.org/10.1287/mnsc.9.3.458..

De Ron, A. J. (1998). Sustainable production: The ultimate result of a continuous improvement. International Journal of Production Economics, 56, 99–110. https://doi.org/10.1016/S0925-5273(98)00005-X

Demirel, P., Li, Q. C., Rentocchini, F., & Tamvada, J. P. (2019) Born to be green: New insights into the economics and management of green entrepreneurship. Small Business Economics, 52, 759–771. https://doi.org/10.1007/s11187-017-9933-z

Driessen, P. H., Hillebrand, B., Kok, R. A., & Verhallen, T. M. (2013). Green new product development: The pivotal role of product greenness. IEEE Transactions on Engineering Management (IEEE), 60(2), 315–326. https://doi.org/10.1109/TEM.2013.2246792

Eltayeb, T. K., Zailani, S., & Ramayah, T. (2011). Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resources Conservation and Recycling, 55(5), 495–506. https://doi.org/10.1016/j.resconrec.2010.09.003

Emovon, I., Norman, R. A., & Murphy, A. J. (2016). An integration of multicriteria decision making techniques with a delay time model for determination of inspection intervals for marine machinery systems. Applied Ocean Research, 59, 65–82. https://doi.org/10.1016/j.apor.2016.05.008

Florida, R., & Davison, D. (2001). Gaining from green management. California Management Review, 43(3), 63–84.

Fu, X., Zhu, Q., & Sarkis, J. (2012). Evaluating green supplier development programs at a telecommunications systems provider. International Journal of Production Economics, 140(1), 357–367.

Gabus, A., & Fontela, E. (1973). Perceptions of the World Problematique: Communication Procedure, Communicating with those bearing Collective Responsibility. Battelle Geneva Research Centre, Geneva.

Gilley, K. M., Worrell, D. L., Davidson, W. N., & El-Jelly, A. (2000). Corporate environmental initiatives and anticipated firm performance: the differential effects of process-driven versus product-driven greening initiatives. Journal of Management, 26(6), 1199–1216. https://doi.org/10.1177/014920630002600607

Govindan, K., Khodaverdi, R., & Vafadarnikjoo, A. (2016a). A grey DEMATEL approach to develop third-party logistics provider selection criteria. Industrial Management and Data Systems, 116(4), 690–722. https://doi.org/10.1108/IMDS-05-2015-0180

Govindan, K., Muduli, K., Devika, K., & Barve, A. (2016b). Investigation of the influential strength of factors on the adoption of green supply chain management practices: An Indian mining scenario. Resources Conservation and Recycling, 107, 185–194. https://doi.org/10.1016/j.resconrec.2015.05.022

Grant, R. M. (1991). The resource-based theory of competitive advantage: Implications for strategy formulation. California Management Review, 33(3), 114–135. https://doi.org/10.2307/41166664

Green Project. (2012). An attempt to define green entrepreneurship. NCCR Policy Brief, 6(1), 1–3.

Hajmohammad, S., Vachon, S., Klassen, R. D., & Gavronski, I. (2013). Lean management and supply management: Their role in green practices and performance. Journal of Cleaner Production, 39, 312–320. https://doi.org/10.1016/j.jclepro.2012.07.028

Hassan, M. G., Abidin, R., Nordin, N., & Yusoff, R. Z. (2016). GSCM practices and sustainable performance: A preliminary insight. Journal of Advanced Management Science, 4(5), 430–434. https://doi.org/10.12720/joams.4.5.430-434

Henriques, I., & Sadorsky, P. (1999). The relationship between environmental commitment and managerial perceptions of stakeholder importance. Academy of Management Journal, 42(1), 87–99. https://doi.org/10.2307/256876

Hilson, G., & Nayee, V. (2002). Environmental management system implementation in the mining industry: A key to achieving cleaner production. International Journal of Mineral Processing, 64(1), 19–41. https://doi.org/10.1016/S0301-7516(01)00071-0

Horbach, J., Rammer, C., & Rennings, K. (2012). Determinants of eco-innovations by type of environmental impact—The role of regulatory push/pull, technology push and market pull. Ecological Economics, 78, 112–122. https://doi.org/10.1016/j.ecolecon.2012.04.005

Hsu, C. W., & Hu, A. H. (2009). Applying hazardous substance management to supplier selection using analytic network process. Journal of Cleaner Production, 17(2), 255–264. https://doi.org/10.1016/j.jclepro.2008.05.004

Huang, Y. C., & Wu, Y. C. (2010). The effects of organizational factors on green new product success: Evidence from high-tech industries in Taiwan. Management Decision, 48(10), 1539–1567. https://doi.org/10.1108/00251741011090324

Hwang, B. G., Zhu, L., & Tan, J. S. H. (2017). Green business park project management: Barriers and solutions for sustainable development. Journal of Cleaner Production, 153, 209–219. https://doi.org/10.1016/j.jclepro.2017.03.210

Ilinitch, A. Y., & Schaltegger, S. C. (1995). Developing a green business portfolio. Long Range Planning, 28(2), 29–38. https://doi.org/10.1016/0024-6301(95)98587-I

Islam, R., Siwar, C., Ludin, N. A., Chowdhury, M. S., & Ibrahim, Y. (2012). Green economy: Assessing the greenness of the Malaysian economy. International Journal of Green Economics, 6(3), 226–242. https://doi.org/10.1504/IJGE.2012.050972

Jeng, D. J. F. (2015). Generating a causal model of supply chain collaboration using the fuzzy DEMATEL technique. Computers and Industrial Engineering, 87, 283–295 https://doi.org/10.1016/j.cie.2015.05.007

Jenkins, H., & Yakovleva, N. (2006). Corporate social responsibility in the mining industry: exploring trends in social and environmental disclosure. Journal of Cleaner Production, 14(3), 271–284. https://doi.org/10.1016/j.jclepro.2004.10.004

Ju-Long, D. (1982). Control problems of grey systems. Systems and Control Letters, 1(5), 288–294. https://doi.org/10.1016/S0167-6911(82)80025-X

Julong, D. (1989). Introduction to grey system theory. Journal of Grey System, 1(1), 1– 24

Kammerer, D. (2009). The effects of customer benefit and regulation on environmental product innovation: Empirical evidence from appliance manufacturers in Germany. Ecological Economics, 68(8), 2285–2295.

Kanchan, U., Kumar, N., & Gupta, A. (2015). GREEN BUSINESS—Way to achieve globally sustainable competitive advantage. Journal of Progressive Research in Social Sciences, 2(2), 92–100.

Keskin, D., Diehl, J. C., & Molenaar, N. (2013). Innovation process of new ventures driven by sustainability. Journal of Cleaner Production, 45, 50–60. https://doi.org/10.1016/j.jclepro.2012.05.012

Kherrazi, S., & Ahsina, K. (2016). Défaillance et politique d’entreprises: Modélisation financière déployée sous un modèle logistique appliqué aux PME marocaines. Revue Gestion et Organisation, 8(1), 53–64. https://doi.org/10.1016/j.rgo.2016.03.006

Kim, Y. (2006). Study on impact mechanism for beef cattle farming and importance of evaluating agricultural information in Korea using DEMATEL, PCA and AHP. Agricultural Information Research, 15(3), 267–279. https://doi.org/10.3173/air.15.267

Kirchhoff, S. (2000). Green business and blue angels. Environmental and Resource Economics, 15(4), 403–420. https://doi.org/10.1023/A:1008303614250

Kirkwood, J., & Walton, S. (2010). What motivates ecopreneurs to start businesses? International Journal of Entrepreneurial Behavior and Research, 16, 204–228. https://doi.org/10.1108/13552551011042799

Klassen, R. D., & Whybark, D. C. (1999). Environmental management in operations: the selection of environmental technologies. Decission Sciences, 30(3), 601–631. https://doi.org/10.1111/j.1540-5915.1999.tb00900.x

Lan, Y.-C. (2011). Reengineering a green business. International Journal of Green Computing, 2(1), 1–11. https://doi.org/10.4018/jgc.2011010101

Lawson, R. (2006). An overview of green economics. International Journal of Green Economics, 1(2), 23–36. https://doi.org/10.1504/IJGE.2006.009335

Lee, S. Y. (2008). Drivers for the participation of small and medium-sized suppliers in green supply chain initiatives. International Journal of Supply Chain Management, 13(3), 185–198. https://doi.org/10.1108/13598540810871235

Lee, V. H., Ooi, K. B., Chong, A. Y. L., & Seow, C. (2014). Creating technological innovation via green supply chain management: An empirical analysis. Expert Systems with Applications, 41(16), 6983–6994. https://doi.org/10.1016/j.eswa.2014.05.022

Lin, R. J., Chen, R. H., & Huang, F. H. (2014). Green innovation in the automobile industry. Industrial Management and Data Systems, 114(6), 886–903. https://doi.org/10.1108/IMDS-11-2013-0482.

Lin, Y., Tseng, M. L., Chen, C. C., & Chiu, A. S. (2011). Positioning strategic competitiveness of green business innovation capabilities using hybrid method. Expert Systems with Applications, 38(3), 1839–1849. https://doi.org/10.1016/j.eswa.2010.07.113

Lin, Y. T., Yang, Y. H., Kang, J. S., & Yu, H. C. (2011). Using DEMATEL method to explore the core competencies and causal effect of the IC design service company: An empirical case study. Expert Systems with Applications, 38(5), 6262–6268. https://doi.org/10.1016/j.eswa.2010.11.092

Liu, J., & Qiao, J. Z. (2014). A grey rough set model for evaluation and selection of software cost estimation methods. Grey Systems Theory Application, 4(1), 3–12. https://doi.org/10.1108/GS-08-2013-0016

Luthra, S., Govindan, K., & Mangla, S. K. (2017). Structural model for sustainable consumption and production adoption—A grey-DEMATEL based approach. Resources, Conservation and Recycling, 125, 198–207. https://doi.org/10.1016/j.resconrec.2017.02.018

Mahamid, I. (2012). Factors affecting contractor’s business failure: Contractors’ perspective. Engineering, Construction and Architectural Management, 19(3), 269–285. https://doi.org/10.1108/09699981211219607

Maruthi, G. D., & Rashmi, R. (2015). Green manufacturing: it’s tools and techniques that can be implemented in manufacturing sectors. Materials Today Proceedings, 2(4), 3350–3355. https://doi.org/10.1016/j.matpr.2015.07.308

Mathiyazhagan, K., Govindan, K., Noorul Haq, A., & Geng, Y. (2013). An ISM approach for the barrier analysis in implementing green supply chain management. Journal of Cleaner Production, 47, 283–297. https://doi.org/10.1016/j.jclepro.2012.10.042

Mathiyazhagan, K., & Haq, A. N. (2013). Analysis of the influential pressures for green supply chain management adoption—An Indian perspective using interpretive structural modeling. International Journal of Advanced Manufacturing Technology, 68(1–4), 817–833.

Megwai, G., Njie, N.I., & Richards, T. (2016). Exploring green economy strategies and policies in developing countries. International Journal of Green Economics, 10(4), 338–357. https://doi.org/10.1504/IJGE.2016.081905

Melay, I., O’Dwyer, M., Kraus, S., & Gast, J. (2017). Green entrepreneurship in SMEs: A configuration approach. International Journal of Entrepreneurial Venturing, 9(1), 1–17. https://doi.org/10.1504/IJEV.2017.082630

Mioara, B., & Mihai, T. (2014). Incidence of green business on developing the entrepreneurial environment from metropolitan area of Ia?i. Procedia Economics and Finance, 15, 1201–1208. https://doi.org/10.1016/S2212-5671(14)00579-6

Mudgal, R. K., Shankar, R., Talib, P., & Raj, T. (2009). Greening the supply chain practices: An Indian perspective of enablers’ relationships. International Journal of Advanced Operations Management, 1(2–3), 151–176. https://doi.org/10.1504/IJAOM.2009.030671

Nelson, R. R., & Winter, S. G. (2009). An evolutionary theory of economic change. Harvard University Press.

Nikbakhsh, E. (2009). Green supply chain management. In Supply chain and logistics in national, international and governmental environment (pp. 195–220). Physica-Verlag HD.

Ninlawan, C., Seksan, P., Tossapol, K., & Pilada, W. (2010). The implementation of green supply chain management practices in electronics industry. Proceedings of the International Multiconference of Engineers and Computer Scientists, 3, 17–19.

O’Neill, K., & Gibbs, D. (2016). Rethinking green entrepreneurship - Fluid narratives of the green economy. Journal of Environment and Planning, 48(9), 1727–1749. https://doi.org/10.1177/0308518X16650453

Ölundh Sandström, G., & Tingström, J. (2008). Management of radical innovation and environmental challenges: Development of the DryQ capacitor at ABB. European Journal of Innovation Management, 11(2), 182–198. https://doi.org/ 10.1108/14601060810869857

Oosterbeek, H., Van Praag, M., & Ijsselstein, A. (2010). The impact of entrepreneurship education on entrepreneurship skills and motivation. European Economic Review, 54, 442–454. https://doi.org/10.1016/j.euroecorev.2009.08.002

Ouyang, Q., Chen, Q., & Zhao, J. (2016). Intelligent sensing sensory quality of Chinese rice wine using near infrared spectroscopy and nonlinear tools. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 154, 42–46. https://doi.org/10.1016/ j.saa.2015.10.011, PubMed: 26513226

Pacheco, D. F., Dean, T. J., & Payne, D. S. (2010). Escaping the green prison: Entrepreneurship and the creation of opportunities for sustainable development. Journal of Business Venturing, 25(5), 464– 480. https://doi.org/10.1016/j.jbusvent.2009.07.006

Pajer, S., Streit, M., Torsney-Weir, T., Spechtenhauser, F., Möller, T., & Piringer, H. (2017). Weightlifter: Visual weight space exploration for multi-criteria decision making. IEEE Transactions on Visualization and Computer Graphics, 23(1), 611–620. https://doi.org/10.1109/TVCG.2016.2598589, PubMed: 27875176.

Peng, X. Y., & Zhang, Y. F. (2014). Study on the real estate green business process management. Advanced Materials Research, 838–841, 3087–3090. https://doi.org/10.4028/www.scientific.net/AMR.838-841.3087

Rajesh, R., & Ravi, V. (2015). Modeling enablers of supply chain risk mitigation in electronic supply chains: A Grey–DEMATEL approach. Computers and Industrial Engineering, 87, 126–139. https://doi.org/10.1016/j.cie.2015.04.028

Rajesh, R., Ravi, V., & Venkata Rao, R. (2015). Selection of risk mitigation strategy in electronic supply chains using grey theory and digraphmatrix approaches. International Journal of Production Research, 53(1), 238–257. https://doi.org/10.1080/00207543. 2014.948579

Rauch, A., & Hulsink, W. (2015). Putting entrepreneurship education where the intention to act lies: An investigation into the impact of entrepreneurship education on entrepreneurial behavior. Academy of Management Learning and Education, 14, 187–204. https://doi.org/10.5465/amle.2012.0293

Ren, J., Liang, H., Dong, L., Gao, Z., He, C., Pan, M., & Sun, L. (2017). Sustainable development of sewage sludge-to-energy in China: Barriers identification and technologies prioritization. Renewable and Sustainable Energy Reviews, 67, 384–396. https://doi.org/10.1016/j.rser.2016.09.024

Rennings, K., & Rammer, C. (2009). Increasing energy and resource efficiency through innovation-an explorative analysis using innovation survey data. SSRN Electronic Journal [Discussion]. 09-056. https://doi.org/10.2139/ssrn.1495761

Salem, M., Shawtari, F. A., Hussain, H. B. I., & Shamsudin, M. F. (2020, April 2). Environmental technology and a multiple approach of competitiveness. Future Business Journal. https://doi.org/10.1186/s43093-020-00012-1

Sarkis, J. (2001). Manufacturing’s role in corporate environmental sustainability— Concerns for the new millennium. International Journal of Operations and Production Management, 21(5/6), 666–686. https://doi.org/10.1108/01443570110390390

Sarkis, J. (2003). A strategic decision framework for green supply chain management. Journal of Cleaner Production, 11(4), 397–409. https://doi.org/10.1016/S0959-6526(02)00062-8

Sarkis, J., Gonzalez-Torre, P., & Adenso-Diaz, B. (2010). Stakeholder pressure and the adoption of environmental practices: The mediating effect of training. Journal of Operations Management, 28(2), 163–176. https://doi.org/10.1016/j.jom.2009.10.001

Shao, J., Taisch, M., & Ortega-Mier, M. (2016). A grey—Decision-Making Trial and Evaluation Laboratory (DEMATEL) analysis on the barriers between environmentally friendly products and consumers: Practitioners’ viewpoints on the European automobile industry. Journal of Cleaner Production, 112, 3185–3194. https://doi.org/10.1016/j.jclepro.2015.10.113

Sharma, V., Kumar, R., & Kumar, R. (2017). QUAT-DEM: Quaternion-DEMATEL based neural model for mutual coordination between UAVs. Information Sciences, 418–419, 74–90. https://doi.org/10.1016/j.ins.2017.08.005

Shrivastava, P., & Hart, S. (1995). Creating sustainable corporations. Business Strategy and the Environment, 4(3), 154–165. https://doi.org/10.1002/bse.3280040307

Simpson, D., Power, D., & Samson, D. (2007). Greening the automotive supply chain: A relationship perspective. International Journal of Operations and Production Management, 27(1), 28–48. https://doi.org/10.1108/01443570710714529

Somsuk, N., & Laosirihongthong, T. (2016). Prioritization of applicable drivers for green supply chain management implementation toward sustainability in Thailand. International Journal of Sustainable Development and World Ecology, 1–17.

Su, C. M., Horng, D. J., Tseng, M. L., Chiu, A. S., Wu, K. J., & Chen, H. P. (2016). Improving sustainable supply chain management using a novel hierarchical grey- DEMATEL approach. Journal of Cleaner Production, 134, 469–481. https://doi.org/10.1016/j.jclepro.2015.05.080

Su, C. S., Shih, C. T., & Hsu, S. C. (2014). Measuring the risk degree of the Green Supply Chain Management System based fuzzy preference relations. Applied Mechanics and Materials, 488–489, 1322–1325, Trans Tech Publications. https://doi.org/10.4028/www.scientific.net/AMM.488-489.1322

Theyel, G. (2000). Management practices for environmental innovation and performance. International Journal of Operations and Production Management, 20(2), 249–266. https://doi.org/10.1108/01443570010304288

Tsai, S. B., Huang, C. Y., Wang, C. K., Chen, Q., Pan, J., Wang, G., Chang, L. C. (2016). Using a mixed model to evaluate job satisfaction in high-tech industries. PLOS ONE, 11(5), 1–13. https://doi.org/10.1371/journal.pone.0154071, PubMed: 27139697

Tseng, M. L. (2009). A causal and effect decision making model of service quality expectation using grey-fuzzy DEMATEL approach. Expert Systems with Applications, 36(4), 7738–7748. https://doi.org/10.1016/j.eswa.2008.09.011

Vafadarnikjoo, A., Mobin, M., Salmon, C., & Javadian, N. (2015). An integrated gray-fuzzy cause and effect approach to determine the most significant categories of project risks. IIE annual conference.). Institute of Industrial and Systems Engineers, 987.

Wang, L., & Wu, C. (2017). Business failure prediction based on two-stage selective ensemble with manifold learning algorithm and kernel-based fuzzy self-organizing map. Knowledge-Based Systems, 121, 99–110. https://doi.org/10.1016/j.knosys.2017.01.016

Weng, H. H. R., Chen, J. S., & Chen, P. C. (2015). Effects of green innovation on environmental and corporate performance: A stakeholder perspective. Sustainability, 7(5), 4997–5026. https://doi.org/10.3390/su7054997

Wu, H. H., Chen, H. K., & Shieh, J. I. (2010). Evaluating performance criteria of employment service outreach program personnel by DEMATEL method. Expert Systems with Applications, 37(7), 5219–5223. https://doi.org/10.1016/j.eswa.2009.12.068

Wu, K. J., Liao, C. J., Tseng, M. L., Lim, M. K., Hu, J., & Tan, K. (2017). Toward sustainability: Using big data to explore the decisive attributes of supply chain risks and uncertainties. Journal of Cleaner Production, 142, 663–676. https://doi.org/10.1016/j.jclepro.2016.04.040

Xia, X., Govindan, K., & Zhu, Q. (2015). Analyzing internal barriers for automotive parts remanufacturers in China using grey-DEMATEL approach. Journal of Cleaner Production, 87, 811–825. https://doi.org/10.1016/j.jclepro.2014.09.044

Yi, H. (2014). Green businesses in a clean energy economy: Analyzing drivers of green business growth in US states. Energy, 68, 922–929. https://doi.org/10.1016/j.energy.2014.02.044

Zhou, K. Z., Brown, J. R., & Dev, C. S. (2009). Market orientation, competitive advantage, and performance: a demand-based perspective. Journal of Business Research, 62(11), 1063–1070. https://doi.org/10.1016/j.jbusres.2008.10.001

Zhu, Q., & Sarkis, J. (2006). An inter-sectoral comparison of green supply chain management in China: Drivers and practices. Journal of Cleaner Production, 14(5), 472–486. https://doi.org/10.1016/j.jclepro.2005.01.003

Zhu, Q., & Sarkis, J. (2007). The moderating effects of institutional pressures on emergent green supply chain practices and performance. International Journal of Cleaner Production Research, 45(18–19), 4333–4355. https://doi.org/10.1080/00207540701440345

Zhu, Q., Sarkis, J., & Lai, K. H. (2008). Green supply chain management implications for closing the loop. Transportation Research Part E: Logistics and Transportation Review, 44(1), 1–18.